King Performance / Racing Main Bearings

King Performance / Racing Main Bearings

FITMENT:

MCBG'16391 MB5442XP - Ford Duratec 2.0 2.3 2.5 NA Engines found in Focus Fusion Ranger Escape Ford Ecoboost ST RS - - Mazda MZR Mazdaspeed 3 6 Miata MX5 2.0 2.3 2.5

MCBG'16743 MB5442MC - Ford Duratec 2.0 2.3 2.5 NA Engines found in Focus Fusion Ranger Escape Ford Ecoboost ST RS - Mazda MZR Mazdaspeed 3 6 Miata MX5 2.0 2.3 2.5

For Ford Duratec Mazda MZR I4 Engines 2.0 2.3 2.5Liter - NA - Ranger, Focus, Fusion, Escape, Mazda 3 5 6 Transit Connect etc Ford Ecoboost 2.0 2.3 found in Focus ST RS Escape Fusion Explorer Taurus - Mazdaspeed 3 2.3 DISI Turbo CX-7 B2300

Successful race engine builders are constantly pushing the limits of load capacity to new levels. Race bearings today inevitably need to match these demands with more competitive bearings. At King Racing we met the challenge with the XP high performance bearings series.

The XP series is a line of bearings with advanced metallurgical and geometric technologies that meet extreme performance loads. It was developed for all performance applications that use forged steel aftermarket crankshafts and produce high loads for extended periods.

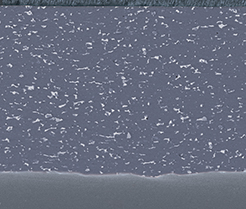

King Racing’s XP series features pMax Black™, a unique tri-metal structure that is 24% harder than any other conventional tri-metal race bearing. pMax Black™ together with the XP geometric features are the ideal combination for performance racing. For more on King Racing technologies visit TechLab

All King Bearings are specifically engineered to withstand the highest loads and RPMs generated by today’s top competition engines. All King Performance Engine Bearings feature:

“Bull’s Eye Tolerance”. King engine bearings have the closest wall tolerances in the industry, with all shells matched to 0.0001”.

Increased Height. Greater rod bearing height improves bearing-to-bore contact/heat transfer and reduces spin potential at high RPM.

Improved Oiling. Mains feature enlarged, chamfered oil holes.

Medium Eccentricity. This enables optimum load distribution and improved oiling.

Dowel Holes. Most rod bearings are available with or without dowel holes.

Narrowed Design. Mains and rods are narrowed for large-radius crankshafts.

We offer the industry’s widest selection of sizes, including special clearance options. With more choices than ever, you’ll find the right King High Performance Engine Bearings for your most demanding applications.

King XP Bearings Features

Applications

High-load, long-duration racing such as circle track, off-road, off-shore, and others that require steel crankshafts

Construction

Enhanced tri-metal copper lead construction with nickel barrier and SecureBond adhesion

Features

15% – 30% greater load capacity than traditional bearings

The SecureBond unique adhesion process, for superior stability between the top and intermediate layers

0.0005” metallurgically enhanced and hardened performance overlay withstands greater loads and better resists surface fatigue

Mains are 1/2 grooved for uncompromised lower shell load capacity

King high strength bi-metal bearings with applied nano-composite polymer coating!

King introduces the new solution for the aftermarket demand of superior service life and performance in modern engines. The new “MC” bearings were developed in the wake of ongoing internal combustion engine development, resulted in ever decreasing minimum oil film thickness values, higher cylinder pressures, temperatures and loads, smaller load carrying bearing surfaces, and lighter components. Additionally, “start/stop” technology produces more frequent mixed lubrication and metal-to-metal contact conditions . The new “MC” bearings feature a nano-composite polymer coating, known as K-340. This new developed polymer coating is designed for applying over relatively hard substrates: bronze, aluminum alloys, sputter overlay, and King silver overlay.

The Bi-Metal structure of the bearing (which consists of Steel back and a strengthened aluminum alloy) is applied with 5-10 microns of the mentioned polymer coating which by itself consists of solid lubricant and ceramic additives. The coating is part of the bearing manufacturing process.

MC Bearings’ Benefits:

• Excellent anti friction and wear resistance properties

• The polymer coating K-340 improves the bearing’s compatability

• High load capacity bearings with outstanding seizure resistance

• Especially suitable for start-stop and hybrid engines that operate constantly under metal-to-metal contact